For around 50 years, JOPP has been producing powder metal parts at the company’s site in Bad Neustadt (Germany).

Developing products in powder metal over many decades, JOPP has a comprehensive customer base from a wide range of industry sectors including automotive. Vertical integration is a key factor in JOPP’s reputation and success. Know-how from manufacturing prototype and production parts complimented by in-house tool manufacturing offers a very convenient “one stop shop” solution.

JOPP has sintering presses with clamping forces up to 300 tons. An additional option Jopp can uniquely offer customers is post sintering machining. For some very complex and detailed designs, the parts can be further processed by machining. They can also be tempered, coated or welded into final assemblies. This offers a very commercially competitive solution when compared to fully machined/fabricated products.

JOPP is convinced the only way to develop a long-term partnership is to achieve maximum added value for its customers.

At a glance: JOPP’s speciality to meet the highest demands in the field of sintering:

Know-how

With approximately 50 years of experience, JOPP is a specialist in all aspects of sintering. JOPP optimise the manufacturing process of its customers product. Only the best processes guarantee added value with the highest quality standards in the industry. JOPP advises and supports its customers with an experienced team during development.

Speed to Market

As a medium-sized family business, JOPP is extremely flexible. With its flat hierarchies, JOPP can make immediate decisions and react extremely quickly.

Optimising Commercials

JOPP uses state-of-the-art machines and has the necessary know-how to manufacture precision parts paying particular attention to cost and economy of scale.

International Presence

JOPP's global presence, with company locations in Germany, the Czech Republic, Hungary, UK, USA, Mexico, Brazil, India and China, enables the company to support its customers worldwide.

JOPP provides first class service supporting its customers during the product development phase and with bespoke designs and optimised processes.

By including JOPP as a development partner at the earliest opportunity during the initial concept design, customers get the very best possibility to optimising the design with valuable hints and innovative ideas. The production of sample parts at an early stage offers significant time advantages to the customer if large series parts are to be produced later.

Sintered part or turned part? A considered choice.

For all projects, JOPP checks the optimum part design with the ideal production process. What is interesting for the customer is that JOPP does not limit itself to sintering technology, but also examines the alternative option of a machined part. This unique selling point is because JOPP also has a competent machining team (Machining Parts) in addition to sintering technology. This means that the advantages of both technologies can be evaluated in order to design and manufacture components in the most appropriate way.

JOPP prides itself by continually investing and using modern machinery and automated processes in large-scale production.

The machines are connected via a network to JOPP’s centralised ERP system SAP via an MDE system. This enables the logistics department to track order status in real time.

At the location in Bad Neustadt (Germany) the following machines are used:

JOPP processes sintered parts with the highest demands on precision. The machinery enables the production of both large and small lot sizes as well as samples for testing.

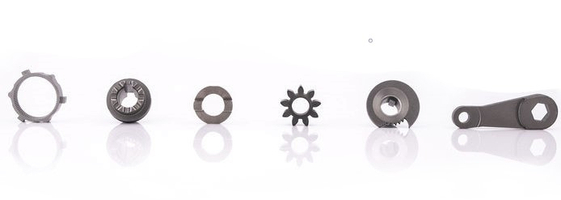

JOPP's expertise is manufacturing technically demanding and precise products for customers in automotive and other industrial sectors. The company specialises in components ranging in diameter from 10 to 81 mm, often with additional requirements such as cleanliness, hardening and coating.

JOPP supplies a wide range of turned parts and assemblies to vehicle manufacturers as well as suppliers in addition to other JOPP divisions where the components are required for higher level assemblies. It is exactly this know-how that makes JOPP the ideal choice when considering simple or complex assemblies.

JOPP sintering technology stands out from the competition with flexible and sophisticated processes together with the unique capability to span different technologies. JOPP combines know-how in the fields of sintering, turning, assembly, plastic moulding, and electronics - and all that worldwide!

The globally recognised phrase synonymous with quality and technology: "Made in Germany", encapsulates everything about JOPP. In addition to the requirements for qualitative and certified processes, JOPP also focuses on expanding to additional industrial standards with zero-defect-strategy and state-of-the-art facilities.

The company complies to automotive standards according to IATF 16949, ISO 14001, ISO 50001 as well as TISAX Level AL2.

JOPP uses an SAP-based planning system with EDI connection and internal material logistics with KANBAN, supermarket and milkrun principles.

The product and process flows are designed according to lean management philosophies and the workplaces according to 5S and One-Piece-Flow.

For large lots, JOPP develops product-specific special solutions for 100 % control of certain characteristics. The in-house plant engineering department provides invaluable support.

In cases where high process capabilities are required, JOPP's experts are able to control the machines taking real time data feedback of measured values directly from the production lines or SPC stations.

JOPP’s measuring and testing equipment far exceeds the industry standard:

JOPP documents and archives measured values, camera images and other data for safety-critical components, linked to individual part identification.