Thanks to its wide technology portfolio, JOPP is interesting both as an employer and a supplier of sophisticated components. Starting with precision machining and powder metal technology, JOPP also manufactures plastic and foamed articles in-house. The portfolio is complimented by a high competency in electronics manufacturing. With these technologies, JOPP secures the advantages of high in-house added value which generates competitive advantages. In corresponding technologies, JOPP competes with the market-leading specialists.

High-performance product development is the foundation of JOPP’s success as a system supplier to automotive, commercial vehicle and off highway customers. JOPP develops mechanical and electronic systems primarily for powertrain and interior products and according to the standards and high expectations of the automotive industry. The company has many patents within its various business sectors and constantly delivers ground breaking innovations in to series production. Prototypes are comprehensively tested utilising the company's state-of-the art in-house test facilities. Sample and equipment construction ensures the rapid assembly of parts for demonstration and testing purposes. JOPP ensures the security of its customers and business partners data in all steps of the product development process via an internationally recognised certified information security management system.

Project Management at JOPP ensures the smooth start of projects into production and is the essential link between customers, sales, product development, purchasing, production planning and quality assurance. In the respective production sites, there are correspondent ramp-up managers who manage the industrialization process on site.

For JOPP, product quality is a key factor for business success. Therefore, the company develops and manufactures its products according to the zero-defect-strategy and permanently follows highest quality targets. In order to meet the continuously increasing standards, JOPP constantly develops processes and structures. The quality management system is certified according to the automotive standard IATF 16949. The standard of measuring and testing equipment, testing and materials laboratory as well as the use of simulation tools is far above the industry standard. For safety-critical components, dimensions and characteristics can be documented digitally. The traceability of components is guaranteed at all times.

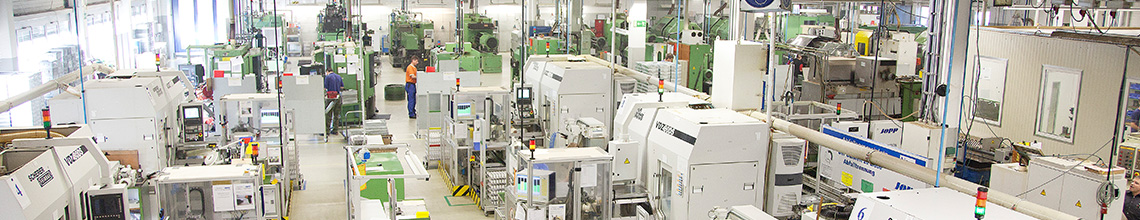

A comparatively high vertical integration makes JOPP a competent partner for challenging projects. The machine and facility park is always state-of-the-art. Special machines are generally built with internal know how, which often generates advantages with regard to response rates and flexibility. All production processes are consequently geared towards LEAN principles and continuously improved.